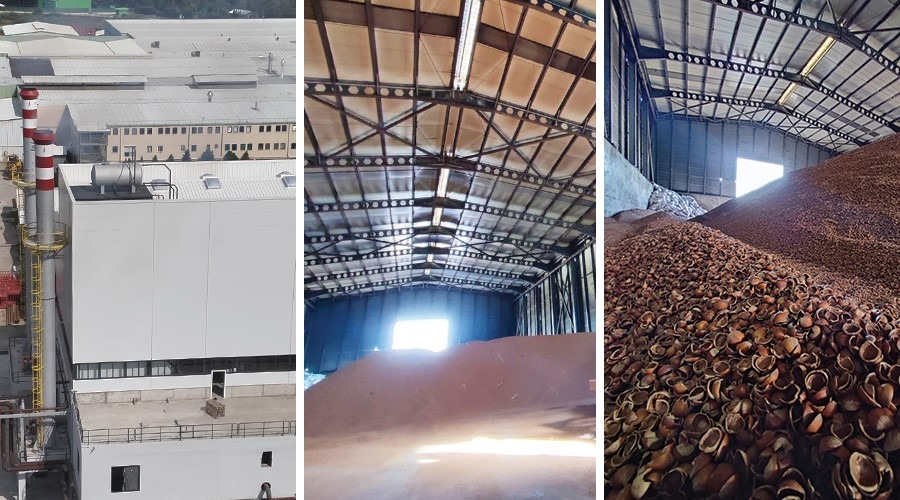

Our Biomass

Boiler, which has been under construction since the beginning of 2024, was put

into operation as of September. Our biomass boiler, which consists of a steam

boiler and a thermal oil

tank and has a daily

burning capacity of 30 tons, will play an important role in our energy

production processes.

Thanks to this investment, a significant decrease in fuel costs has been achieved, while at the same time, we have come one step closer to our sustainability goals with the use of environmentally friendly fuel. In addition, since the hazelnut shells we will use as fuel are supplied by suppliers in the region where our factory is located, it will also contribute to the sustainability of the local economy. In our biomass boiler in addition to hazelnut shell, fuels such as walnut shell, almond shell, pomace (olive kernel), wood chips, pine cones can be burned as well.

With this Biomass Energy Investment, we aim to achieve a significant reduction in C02 emissions.

We are happy to have put this technology into operation in order to both reduce our carbon footprint and increase energy efficiency, and to share this very important investment with all our partners.

Green Energy, Better Future !