Our Belief in Environmentally Friendly Production

Considering sustainability in all production processes, Lila Lace & Fabric takes the necessary arrangements in production processes with this precision. Knowing that we must strive together today to save the future of the world, Lila Lace & Fabric is one of the few companies investing in today for a better future. Lila adopts an environmentally friendly attitude, always taking advantage of opportunities to improve itself by thinking about the environmental impact of its activities.

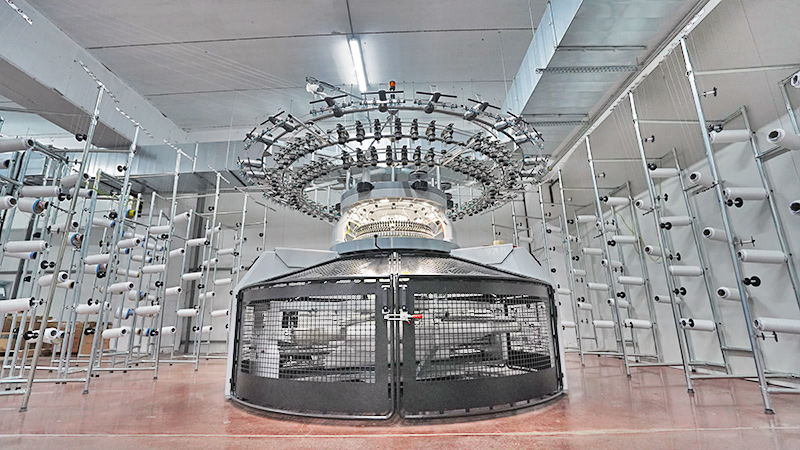

Establishing partnerships with the world`s most ambitious environmentally friendly companies and observing international certificates in every stakeholder, Lila Lace & Fabric works with top quality yarn suppliers and environmentally friendly dye-chemical companies that do not harm human health. It also develops recycled polyamide laces, recycled polyamide and polyester, and warped and circular knitted fabrics to support natural life and have minimal impact on the environment. Lila Lace & Fabric minimizes energy consumption with many projects it carries out.

Apart from production, Lila Lace & Fabric, which has an environmentally friendly approach in terms of products, develops sustainable fabric production studies under the brand "Relife", which has recyclable contents every season. Lila Lace & Fabric also develops lace with lace Tencell/lyocell yarn under the brand name Lilacell.

Investing in innovative energy and water-saving machine parks by following continuous technological developments, Lila successfully passes comprehensive inspections carried out regularly every year. Aiming to raise its working methods to world standards in order to create a sustainable production model, Lila is registered with the valid certificates of many international organizations. All products produced by the company, which has OEKOTEX, GRS, RCS, ISO 50001 and ISO 9001 certificates, are evaluated for energy, water and waste management with Higg, INDEX, FEM & FSLM modules at least once a year.

Lila Lace& Fabric has saved 20% water and energy with new dyeing machines equipped with the latest technology and 10% energy with ram machines.

Our Biomass Boiler, which has been under construction since the beginning of 2024, was put into operation as of September. Our biomass boiler, which consists of a steam boiler and a thermal oil tank and has a daily burning capacity of 30 tons, will play an important role in our energy production processes.

Thanks to this investment, a significant decrease in fuel costs has been achieved, while at the same time, we have come one step closer to our sustainability goals with the use of environmentally friendly fuel. In addition, since the hazelnut shells we will use as fuel are supplied by suppliers in the region where our factory is located, it will also contribute to the sustainability of the local economy. In our biomass boiler in addition to hazelnut shell, fuels such as walnut shell, almond shell, pomace (olive kernel), wood chips, pine cones can be burned as well.

With this investment, we aim to significantly reduce our carbon emissions: With Biomass Energy Project, 6,5m tons/year CO2 emission reduction is aimed in 2024.

We are happy to have put this technology into operation in order to both reduce our carbon footprint and increase energy efficiency, and to share this very important investment with all our partners.

Green Energy, Better Future !